|

Soft Urethane Acrylate

|

|

| Product Name |

Features |

Dilution(%) |

Acryl

Functionality |

MW(GPC) |

Color (APHA) |

viscosity

(cps @ 25℃) |

Refractive

Index |

Tg(℃) |

Advantage, recommendation points |

TDS |

MSDS |

| SUO-2371 |

Aliphatic Urethane |

- |

1 |

20,500 |

< 100 |

30,000 ~ 50,000 |

1.456 ~ 1.460 |

-50 |

Good flexibility, adhesion, low shrink |

|

|

| SUO-2126 |

Aliphatic Urethane |

- |

1 |

6,000 |

< 100 |

10,000 ~ 20,000 |

1.461 ~ 1.465 |

-52 |

Good flexibility, adhesion, low shrink |

|

|

| SUO-2171 |

Aliphatic Urethane |

- |

1 |

17,100 |

< 100 |

50,000 ~ 90,000 |

1.459 ~ 1.463 |

-48 |

Good flexibility, adhesion, low shrink |

|

|

| SUO-2101 |

Aliphatic Urethane |

- |

1 |

49,200 |

< 100 |

15,000 ~ 25,0003) |

1.458 ~ 1.462 |

-48 |

Excellent flexibility, Good adhesion |

|

|

| UA-222 |

Aromatic Urethane |

- |

2 |

1,500 |

< 150 |

5,000 ~ 9,000 |

1.503 ~ 1.507 |

3 |

Low viscosity, good adhesion, low tacky |

|

|

| SUO-210 |

Aliphatic Urethane |

- |

2 |

1,600 |

< 100 |

3,000 ~ 9,000 |

1.481 ~ 1.485 |

12 |

Low viscosity, good flexibility and elasticity |

|

|

| SUO-7301 |

Aliphatic Urethane |

- |

2 |

5,000 |

< 150 |

7,000 ~ 13,000 |

1.477 ~ 1.481 |

19 |

Low viscosity, good elasticity, low tacky |

|

|

| SUO-1020NI |

Aliphatic Urethane |

- |

2 |

1,300 |

< 150 |

8,000 ~ 13,0003) |

1.482 ~ 1.486 |

50 |

Good toughness, chemical resistance, low yellowness |

|

|

| SUO-1020 |

Aliphatic Urethane |

IBOA 20 |

2 |

1,200 |

< 150 |

35,000 ~ 45,000 |

1.480 ~ 1.484 |

39 |

Good toughness, chemical resistance, low yellowness |

|

|

| SUO-1202I20 |

Aliphatic Urethane |

IBOA 20 |

2 |

22000 |

< 200 |

10,000 - 20,0002) |

1.471 ~ 1.475 |

-17 |

Good flexibility, adhesion, low shrink |

|

|

| SUO-4130 |

Aliphatic Urethane |

- |

2 |

10,500 |

< 100 |

20,000 ~ 40,0003) |

1.477 ~ 1.481 |

-25 |

Good adhesion, flexibility, adhesion to metallized foil |

|

|

| SUO-4140I10 |

Aliphatic Urethane |

IBOA 10 |

2 |

10,000 |

< 100 |

4,000 ~ 10,0003) |

1.481 ~ 1.485 |

- |

Good adhesion, flexibility, adhesion to metallized foil |

|

|

| SUO-9103I20 |

Aliphatic Urethane |

IBOA 20 |

2 |

43,700 |

< 100 |

20,000 ~ 35,0003) |

1.460 ~ 1.464 |

-54 |

Excellent flexibility, good elasticity, good adhesion |

|

|

| SUO-M2000 |

Aliphatic Urethane |

- |

2 |

10,000 |

< 100 |

20,000 ~ 40,000 |

1.467 ~ 1.471 |

-53 |

Excellent flexibility, Good adhesion, wrinkle resistance |

|

|

| SUO-H7000 |

Aliphatic Urethane |

- |

2 |

23,500 |

< 100 |

25,000 ~ 45,000 |

1.457 ~ 1.461 |

-55 |

Excellent flexibility, good elasticity, good adhesion |

|

|

| SUO-2172 |

Aliphatic Urethane |

- |

2 |

14,200 |

< 100 |

10,000 ~ 20,0001) |

1.460 ~ 1.464 |

-50 |

Excellent flexibility, good elasticity, good adhesion |

|

|

| SUO-3110B60 |

Aliphatic Urethane |

BAc 40 |

2 |

8,100 |

< 100 |

300 ~ 600 |

- |

-15 |

Better elongation. Low modulus, soft feel effect |

|

|

| SUO-3110H20 |

Aliphatic Urethane |

HDDA 20 |

2 |

7,200 |

< 100 |

40,000 ~ 50,000 |

1.478 ~ 1.482 |

-7 |

Better elongation. Low modulus, soft feel effect |

|

|

| SUO-3210 |

Aliphatic Urethane |

- |

2 |

9,400 |

< 150 |

10,000 ~ 20,0003) |

1.485 ~ 1.489 |

-25 |

High elasticity, good toughness |

|

|

| SUO-300 |

Aliphatic Urethane |

- |

2 |

5,700 |

< 100 |

20,000 ~ 40,000 |

1.489 ~ 1.493 |

7 |

Good elasticity, flexibility, adhesion and low tacky |

|

|

|

|

Hard Urethane Acrylate (Multi-Functional)

|

|

| Product Name |

Features |

Dilution(%) |

Acryl

Functionality |

MW(GPC) |

Color (APHA) |

viscosity

(cps @ 25℃) |

Refractive

Index |

Tg(℃) |

Advantage, recommendation points |

TDS |

MSDS |

| SUO-7620 |

Aliphatic Urethane |

- |

6 |

2,000 |

< 100 |

18,000 ~ 30,000 |

1.490 ~ 1.494 |

60 |

High hardness, good scratch resistance, low viscosity |

|

|

| SUO-7630 |

Aliphatic Urethane |

- |

6 |

1,900 |

< 100 |

2,000 - 6,0002) |

1.493 ~ 1.497 |

55 |

High hardness, good scratch resistance |

|

|

| SUO-7640 |

Aliphatic Urethane |

- |

6 |

1,700 |

< 100 |

2,000 - 6,0002) |

1.493 ~ 1.497 |

80 |

High hardness, good scratch resistance |

|

|

| SUO-7650 |

Aliphatic Urethane |

- |

6 |

2,100 |

< 100 |

5,000 - 15,0002) |

1.496 ~ 1.500 |

88 |

High hardness, good scratch resistance |

|

|

| SUO-7690 |

Aliphatic Urethane |

- |

6 |

11,000 |

< 100 |

30,000 ~ 50,000 |

1.469 ~ 1.473 |

49 |

High hardness, good scratch resistance |

|

|

| SUO-1206H20 |

Aliphatic Urethane |

HDDA 20 |

6 |

14,200 |

< 100 |

50,000 - 70,0002) |

1.477 ~ 1.481 |

80 |

High hardness, good scratch resistance, better flexibility |

|

|

| SUO-7910 |

Aliphatic Urethane |

- |

9 |

8,300 |

< 100 |

5,000 ~ 10,0003) |

1.497 ~ 1.501 |

87 |

High hardness, good scratch resistance |

|

|

| SUO-7920 |

Aliphatic Urethane |

- |

9 |

2,600 |

< 100 |

35,000 ~ 55,000 |

1.494 ~ 1.498 |

80 |

High hardness, good scratch resistance |

|

|

| SUO-7100LC |

Aliphatic Urethane |

- |

10 |

2,600 |

< 100 |

5,000 - 9,0002) |

1.493 ~ 1.497 |

60 |

Excellent hardness, scratch resistance |

|

|

| SUO-7100LV |

Aliphatic Urethane |

- |

10 |

2,100 |

< 100 |

3,000 - 7,0002) |

1.492 ~ 1.496 |

50 |

Excellent hardness, scratch resistance, better viscosity |

|

|

| SUO-7100F |

Aliphatic Urethane |

- |

10 |

7,600 |

< 100 |

5,000 - 10,0002) |

1.477 ~ 1.481 |

45 |

Excellent hardness, scratch resistance, better flexibility |

|

|

| SUO-7100M |

Aliphatic Urethane |

- |

10 |

2,200 |

< 100 |

1,000 ~ 5,0003) |

1.492 ~ 1.496 |

50 |

Excellent hardness and scratch resistance |

|

|

| SUO-1500E |

Aliphatic Urethane |

- |

15 |

9,500 |

< 100 |

10,000 ~ 25,0002) |

1.489 ~ 1.493 |

46 |

Excellent hardness, abrasion, chemical, scratch resistance |

|

|

| SUO-1500T |

Aliphatic Urethane |

- |

15 |

7,400 |

< 100 |

5,000 ~ 9,0003) |

1.494 ~ 1.498 |

40 |

Excellent hardness, abrasion, chemical, scratch resistance |

|

|

|

|

Special type Urethane Acrylate

|

|

| Product Name |

Features |

Dilution(%) |

Acryl

Functionality |

MW(GPC) |

Color (APHA) |

viscosity

(cps @ 25℃) |

Refractive

Index |

Tg(℃) |

Advantage, recommendation points |

TDS |

MSDS |

| SUO-S3000 |

Aliphatic Urethane |

- |

2 |

7,000 |

< 150 |

15,000 ~ 25,000 |

1.455 ~ 1.459 |

30 |

Easy cleaning, good slip effect, better flexibility |

|

|

| SUO-S600NM |

Aliphatic Urethane |

- |

6 |

5,500 |

< 200 |

8,000 ~ 12,0002) |

1.470 ~ 1.474 |

55 |

Easy cleaning, good slip effect, better hardness |

|

|

| SUO-FS500 |

Aliphatic Urethane |

- |

6 |

3,700 |

< 3G |

5,000 ~ 15,0002) |

1.483 ~ 1.487 |

46 |

Good compatibility, easy clean, slip effect, high WCA |

|

|

| Product Name |

Features |

Dilution(%) |

Acryl

Functionality |

MW(GPC) |

Color (APHA) |

viscosity

(cps @ 25℃) |

Refractive

Index |

Tg(℃) |

Advantage, recommendation points |

TDS |

MSDS |

| SUO-8130 |

Aliphatic Urethane |

- |

2 |

33,000 |

< 5G |

20,000 ~ 30,0003) |

1.512 ~ 1.516 |

-32 |

Hydrolytic stability, good chemical resistance |

|

|

| SUO-8628 |

Aliphatic Urethane |

- |

2 |

13,400 |

< 5G |

5,000 ~ 20,000 |

1.511 ~ 1.515 |

-34 |

Hydrolytic stability, good chemical resistance, good adhesion |

|

|

| SUO-H8155 |

Aliphatic Urethane |

- |

1 |

12,000 |

< 100 |

20,000 ~ 30,0003) |

1.479 ~ 1.483 |

-20 |

Excellent adhesion, good color (low yellowness) |

|

|

| SUO-H8130 |

Aliphatic Urethane |

- |

2 |

10,300 |

< 100 |

25,000 ~ 45,0003) |

1.482 ~ 1.486 |

-36 |

Good adhesion, hydrolysis resistance (Hydrophobicity) |

|

|

| SUO-H8628 |

Aliphatic Urethane |

- |

2 |

6,000 |

< 100 |

20,000 ~ 40,000 |

1.477 ~ 1.481 |

-38 |

Good adhesion, hydrolysis resistance (Hydrophobicity) |

|

|

| SUO-H8803 |

Aliphatic Urethane |

- |

4 |

- |

< 100 |

40,000 ~ 60,0003) |

1.482 ~ 1.486 |

40 |

High chemical resistance, good hydrolysis resistance |

|

|

| Product Name |

Features |

Dilution(%) |

Acryl

Functionality |

MW(GPC) |

Color (APHA) |

viscosity

(cps @ 25℃) |

Refractive

Index |

Tg(℃) |

Advantage, recommendation points |

TDS |

MSDS |

| SFA-001 |

Acrylate monomer |

- |

1 |

400 |

<200 |

<20 |

1.351 ~ 1.356 |

20 |

Extremely low viscosity, flexibility, low RI (refractive index) |

|

|

| SFA-335 |

Aliphatic Urethane |

- |

2 |

3,000 |

Slightly haze |

250 ~ 450 |

1.335 ~ 1.339 |

35 |

Low viscosity, low RI, high WCA (water contact angle) |

|

|

| SFA-347 |

Aliphatic Urethane |

- |

2 |

- |

Slightly haze |

1,000 ~ 1,500 |

1.345 ~ 1.355 |

40* |

Low viscosity, low RI, high WCA (water contact angle) |

|

|

| SFA-380 |

Aliphatic Urethane |

- |

2 |

3,300 |

Slightly haze |

7,000 ~ 10,0002) |

1.378 ~ 1.382 |

38 |

Flexibility, low RI, high (WCA) water contact angle |

|

|

| SFA-387 |

Aliphatic Urethane |

- |

2 |

- |

Slightly haze |

6,000 ~ 10,0003) |

1.385 ~ 1.389 |

45* |

Flexibility, low RI, high (WCA) water contact angle |

|

|

| SFA-420 |

Aliphatic Urethane |

- |

6 |

2,400 |

Slightly haze |

20,000 ~ 40,0002) |

1.419 ~ 1.425 |

58 |

Better hardness, low RI, high (WCA) water contact angle |

|

|

| SFA-480 |

Aliphatic Urethane |

- |

6 |

1,400 |

Slightly haze |

5,000 ~ 12,0002) |

1.478 ~ 1.484 |

60 |

Good scratch and chemical resistance, good levelling |

|

|

| SBPF-022 |

Acrylate monomer |

- |

1 |

550 |

<200 |

8002) |

1.596 ~ 1.600 |

- |

High RI(Refractive Index), Low viscosity |

|

|

|

|

Dual curing type PUA

|

|

| Product Name |

Features |

NCO

Functionality |

Acryl

Functionality |

MW(GPC) |

Color (APHA) |

viscosity

(cps @ 25℃) |

NCO Content

(%) |

Tg(℃) |

Advantage, recommendation points |

TDS |

MSDS |

| SUO-1811N |

Aliphatic Urethane |

2 |

1 |

1,200 |

< 100 |

4,500 ~ 9,000 |

17.94 |

- |

Good adhesion, chemical resistance, fast reactivity |

|

|

| SUO-1821N |

Aliphatic Urethane |

1 |

1 |

6,100 |

< 100 |

30,000 ~ 50,0003) |

2.6 |

- |

Good flexibility, adhesion, stability |

|

|

| SUO-1831N |

Aliphatic Urethane |

2 |

1 |

1,800 |

< 100 |

18,000 ~ 28,000 |

11.8 |

- |

Good adhesion, chemical resistance, fast reactivity |

|

|

| SUO-1841N |

Aliphatic Urethane |

1 |

1.5 |

1,600 |

< 100 |

55,000 ~ 75,000 |

8 |

- |

Fast UV reactivity, good adhesion, flexibility |

|

|

| SUO-1881N |

Aliphatic Urethane |

2 |

1 |

1,300 |

< 100 |

10,000 ~ 20,000 |

13.13 |

- |

Good adhesion, chemical resistance, fast reactivity |

|

|

| SUO-2126N |

Aliphatic Urethane |

1 |

1 |

6,000 |

< 100 |

20,000 ~ 30,000 |

0.66 |

- |

Excellent flexibility and elongation |

|

|

| SUO-7301N |

Aliphatic Urethane |

1 |

2 |

5,300 |

< 150 |

5,000 ~ 9,000 |

3.25 |

- |

Good flexibility, fast uv curing reaction |

|

|

| Product Name |

Features |

OH

Functionality |

Acryl

Functionality |

MW(GPC) |

Color (APHA) |

viscosity

(cps @ 25℃) |

OH Value

(mg KOH/g) |

Tg(℃) |

Advantage, recommendation points |

TDS |

MSDS |

| SUO-1611H |

Aliphatic Urethane |

1 |

1 |

4,000 |

< 300 |

10,000 ~ 20,000 |

49 |

- |

Good adhesion, chemical resistance |

|

|

| SUO-1621H |

Aliphatic Urethane |

1 |

1 |

8,700 |

< 300 |

90,000 ~ 110,000 |

27 |

- |

Good adhesion, flexibility |

|

|

| Product Name |

Features |

Epoxy

Functionality |

Acryl

Functionality |

MW |

Color (APHA) |

viscosity

(cps @ 40℃) |

Refractive Index |

Total Cl

(ppm) |

Advantage, recommendation points |

TDS |

MSDS |

| SEA-H187AI |

BPA Epoxy/Acrylate |

1 |

2 |

1,300 |

< 300 |

2,000 ~ 6,0003) |

1.545 ~ 1.549 |

<900 |

Excellent mechanical properties, adhesion and reactivity |

|

|

| SEA-A130H |

BPA Epoxy/Acrylate |

0.6 |

1.4 |

450** |

<500 |

15,000 ~ 25,0001) |

1.560 ~ 1.570 |

<500 |

Excellent mechanical properties, adhesion and reactivity |

|

|

| SEA-A150H |

BPA Epoxy/Acrylate |

1 |

1 |

420** |

<500 |

7,000 ~ 12,0001) |

1.560 ~ 1.570 |

<500 |

Excellent mechanical properties, adhesion and reactivity |

|

|

| SEA-A170H |

BPA Epoxy/Acrylate |

1.4 |

0.6 |

390** |

<500 |

2,000 ~ 5,0001) |

1.560 ~ 1.570 |

<500 |

Excellent mechanical properties, adhesion and reactivity |

|

|

| SEA-F130H |

BPA Epoxy/Acrylate |

0.6 |

1.4 |

420** |

<700 |

7,000 ~ 11,0001) |

1.560 ~ 1.570 |

<700 |

Excellent mechanical properties, adhesion and reactivity |

|

|

| SEA-F150H |

BPA Epoxy/Acrylate |

1 |

1 |

390** |

<700 |

2500 ~ 5,5001) |

1.560 ~ 1.570 |

<700 |

Excellent mechanical properties, adhesion and reactivity |

|

|

| SEA-F170H |

BPA Epoxy/Acrylate |

1.4 |

0.6 |

360** |

<700 |

500 ~ 2,5001) |

1.560 ~ 1.570 |

<700 |

Excellent mechanical properties, adhesion and reactivity |

|

|

|

|

Adhesion Promoter

|

|

| Product Name |

Features |

Carboxyl

Functionality |

Acryl

Functionality |

MW(GPC) |

Color (APHA) |

viscosity

(cps @ 25℃) |

Acid Value

(mg KOH/g) |

Tg(℃) |

Advantage, recommendation points |

TDS |

MSDS |

| SAM-HS100 |

Phosphoric Acid |

1 |

1 |

180 |

200 |

2,500 ~ 6,500 |

400 ~ 600 |

- |

low viscosity, good adhesion and flexibility |

|

|

| SAM-C100 |

Carboxylic Acid |

1 |

1.5 |

400 |

100 |

2,500 ~ 4,500 |

200 ~ 300 |

- |

low viscosity, good adhesion and flexibility |

|

|

|

|

Soft Urethane Acrylate (Tin free)

|

|

| Product Name |

Features |

Dilution(%) |

Acryl Functionality |

MW(GPC) |

Color (APHA) |

viscosity

(cps @ 25℃) |

Refractive

Index |

Tg(℃) |

Advantage, recommendation points |

TDS |

MSDS |

| SUO-4130TF |

Aliphatic Urethane |

- |

2 |

11,000 |

<100 |

40,000 ~ 60,0003) |

1.477 ~ 1.481 |

-20 |

Good adhesion, flexibility, Tin free |

|

|

| SUO-7301TF |

Aliphatic Urethane |

- |

2 |

8,000 |

<200 |

10,000 ~ 30,000 |

1.477 ~ 1.481 |

-15 |

Low viscosity, good elasticity, low tacky, Tin free |

|

|

|

|

Hard Urethane Acrylate (Tin free)

|

|

| Product Name |

Features |

Dilution(%) |

Acryl Functionality |

MW(GPC) |

Color (APHA) |

viscosity

(cps @ 25℃) |

Refractive Index |

Tg(℃) |

Advantage, recommendation points |

TDS |

MSDS |

| SUO-7620TF |

Aliphatic Urethane |

- |

6 |

2,000 |

<200 |

16,000 ~ 28,000 |

1.490 ~ 1.494 |

60 |

High hardness, good scratch resistance, Tin free |

|

|

|

|

Epoxy Acrylate I

|

|

| Product Name |

Features |

Dilution(%) |

Functionality |

MW(GPC) |

Color (APHA) |

viscosity

(cps @ 25℃) |

Refractive

Index |

Advantage, recommendation points |

TDS |

MSDS |

| SEA-187 |

BPA Epoxy |

- |

2 |

720 |

< 100 |

4,000 ~ 8,0003) |

1.556 ~ 1.560 |

Good adhesion, scratch and chemical resistance |

|

|

| SEA-450M40 |

BPA Epoxy |

OPPEA 40 |

2 |

2,000 |

< 200 |

10,000 ~ 20,0002) |

1.574 ~ 1.578 |

Good adhesion, scratch and chemical resistance |

|

|

| SEA-4125 |

BPA-PO |

- |

2 |

950 |

< 2G |

3,000 ~ 13,0001) |

1.531 ~ 1.535 |

Excellent adhesion and flexibility |

|

|

| SEA-Z250 |

BPZ Epoxy |

- |

2 |

730 |

< 200 |

20,000 ~ 40,0003) |

1.564 ~ 1.568 |

Excellent heat resistance and chemical resistance |

|

|

| SUO-544 |

Biphenyl Epoxy |

- |

1.5 |

450 |

< 300 |

1,000 ~ 3,000 |

1.581 ~ 1.585 |

High refractive index, good adhesion |

|

|

| SEA-650 |

Sulfuric Epoxy |

- |

2 |

760 |

< 5G |

20,000 ~ 40,0001) |

1.582 ~ 1.587 |

High refractive index, good adhesion |

|

|

| SEA-820 |

Biphenyl Novolac Epoxy |

OPPEA 20 |

2 - 2.5 |

960 |

< 5G |

Semi-Solid |

1.604 ~ 1.608 |

High refractive index, High chemical resistance |

|

|

| SEA-700BA20 |

Fluorene Epoxy |

BZA 20 |

2 |

750 |

< 5G |

3,000 ~ 7,0003) |

1.598 ~ 1.602 |

High refractive index, High chemical resistance |

|

|

|

|

Epoxy Acrylate II

|

|

| Product Name |

Features |

Dilution(%) |

NV

(wt%) |

MW(GPC) |

Color (APHA) |

viscosity

(cps @ 25℃) |

Acid value

(mg KOH/g) |

Advantage, recommendation points |

TDS |

MSDS |

| JEA-1090PM |

Cresol Novolac Epoxy |

PMA |

63 - 67 |

4,800 |

< 5G |

10,000 ~ 30,000 |

80 - 90 |

High acid value, good adhesion, dispersionability |

|

|

| SEA-V236M50 |

Novolac Epoxy Acrylate |

TMPTA 50 |

- |

2,300 |

< 200 |

5,000 ~ 25,000 |

<2 |

High heat, chemical resistance |

|

|

|

|

Prism Sheet Imprinting

|

|

| Grade |

Refractive Index |

Viscosity (cps @25℃) |

Anti-Scratch* |

Color (APHA) |

Features |

Cure Condition (mJ/㎤) |

TDS |

MSDS |

| SSP-0302LV |

1.529 - 1.533 |

120 - 180 |

1,000g↑ |

250 max |

Low viscosity |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-5380S |

1.525 - 1.530 |

300 - 400 |

1,000g↑ |

250 max |

Good Self healing |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-0314S |

1.528 - 1.531 |

200 - 300 |

2,000g↑ |

250 max |

Good Self healing |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-0565SD |

1.548 - 1.552 |

150 - 300 |

600g↑ |

250 max |

Low viscosity |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-0566SD |

1.548 - 1.552 |

400 - 500 |

1,500g↑ |

250 max |

Good Self healing |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-5500S |

1.548 - 1.552 |

500 - 800 |

600g↑ |

250 max |

- |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-0575S |

1.550 - 1.560 |

1,000 - 1,500 |

600g↑ |

250 max |

- |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-5711S |

1.562 - 1.565 |

600 - 1,000 |

600g↑ |

250 max |

High RI |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-0775S |

1.565 - 1.570 |

2,500 - 3,500 |

600g↑ |

250 max |

High RI |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| Grade |

Refractive Index |

Viscosity (cps @25℃) |

Anti-Scratch* |

Color (APHA) |

Features |

Cure Condition (mJ/㎤) |

TDS |

MSDS |

| SSP-5502N |

1.545 - 1.552 |

1,200 - 1,400 |

- |

250 max |

Normal Type |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-5701N |

1.570 - 1.575 |

800 - 1,000 |

- |

250 max |

Normal Type |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-5801N |

1.579 - 1.583 |

1,000 - 1,200 |

- |

250 max |

Normal Type |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SUP-579 |

1.578 - 1.581 |

1,500 - 1,900 |

- |

250 max |

High RI Grade |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-6000N |

1.597 - 1.603 |

1,000 - 1,500 |

- |

250 max |

High RI Grade |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-6100N |

1.607 - 1.612 |

2,000 - 2,500 |

- |

250 max |

High RI Grade |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-6100LV |

1.605 - 1.610 |

500 - 700 |

- |

250 max |

High RI Grade,

Low Viscosity |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-H6214 |

1.620 - 1.625 |

400 - 600 |

50 - 100g |

250 max |

Inorganic Hybrid Type, Low S/H |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-H6300 |

1.630 - 1.640 |

600 - 800 |

- |

250 max |

Inorganic Hybrid Type |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| SSP-H6500 |

1.650 - 1.653 |

1,000 - 1,500 |

- |

250 max |

Inorganic Hybrid Type |

BL 100↑ + Hg or Metal 400-500↑ |

|

|

| Grade |

Refractive Index |

Viscosity (cps @25℃) |

Color (APHA) |

Application |

Features |

Cure Condition (mJ/㎤) |

TDS |

MSDS |

| SSA-3100 |

1.480 - 1.500 |

300 - 400 |

250 max |

Adhesives |

Non-Solvent, N.V 100% |

Hg or Metal Lamp 400-500↑ |

|

|

| SSA-5000 |

1.420 - 1.450 |

15 - 35 |

250 max |

Adhesives |

Solvent Type, N.V 50% |

Hg or Metal Lamp 400-500↑ |

|

|

| SSA-5001 |

1.485 - 1.495 |

700 - 900 |

250 max |

Adhesives |

Non-Solvent, N.V 100% |

Hg or Metal Lamp 400-500↑ |

|

|

| SSA-5010 |

1.490 - 1.500 |

300 - 400 |

250 max |

Adhesives |

Non-Solvent, N.V100% |

Hg or Metal Lamp 400-500↑ |

|

|

| SSP-0116BT |

1.500 - 1.520 |

20 - 30 |

250 max |

Bottom Prism Resin |

Low Viscosity |

BL Lamp 100↑ |

|

|

| SSP-0302BT |

1.528 - 1.532 |

100 - 200 |

250 max |

Bottom Prism Resin |

- |

BL Lamp 100↑ |

|

|

| SSP-0507S |

1.550 - 1.555 |

1,000 - 2,000 |

250 max |

Bottom Prism Resin |

- |

BL Lamp 100↑ |

|

|

| SSP-5500BT |

1.552 - 1.558 |

80 - 120 |

250 max |

Bottom Prism Resin |

Low Viscosity |

BL Lamp 100↑ |

|

|

|

|

Back Coating

|

|

| Grade |

Refractive Index |

Viscosity (cps @25℃) |

Color (APHA) |

Features |

Cure Condition (mJ/㎤) |

TDS |

MSDS |

| SUD-460 |

1.455 - 1.465 |

30 - 50 |

250 max |

Imprinting(Pattern) Type, N.V 100% |

Hg or Metal Lamp 400-500↑ |

|

|

| SSB-4664AS |

1.470 - 1.490 |

50 - 100 |

250 max |

Imprinting(Pattern) Type, N.V 100% |

Hg or Metal Lamp 400-500↑ |

|

|

| SSB-5101AS |

1.460 - 1.490 |

300 - 400 |

250 max |

Solvent Bead Coating Type, N.V 100% |

Hg or Metal Lamp 400-500↑ |

|

|

|

|

High RI Resins

|

|

| Grade |

Refractive Index |

Viscosity (cps @25℃) |

Color (APHA) |

Features |

Application |

TDS |

MSDS |

| SHO-6100 |

1.600 - 1.607 |

60,000 - 70,000 |

250 max |

Organic oligomer |

Display film coating, security film coating |

|

|

| SHO-H6200 |

1.613 - 1.623 |

32,000 - 36,000 |

Haze liquid |

Organic/Inorganic hybrid |

Display film coating, security film coating |

|

|

| SHO-H6300 |

1.623 - 1.633 |

5,000 - 8,000 |

Haze liquid |

Organic/Inorganic hybrid |

Display film coating, security film coating |

|

|

| SHO-H6500 |

1.642 - 1.652 |

1,500 - 2,500 |

Haze liquid |

Organic/Inorganic hybrid |

Display film coating, security film coating |

|

|

|

|

Light Guard Panel Coating

|

|

| Grade |

Refractive Index |

Viscosity (cps @25℃) |

Color (APHA) |

Features |

Cure Condition (mJ/㎤) |

TDS |

MSDS |

| SSC-1410IP |

1.460 -1.475 |

100 - 200 |

250 max |

UV Imprinting on LGP, Good Adhesion to PMMA |

Hg or Metal Lamp 400-500↑ |

|

|

| SSC-1610IP |

1.460 -1.475 |

100 - 200 |

250 max |

UV Imprinting on LGP, Good Adhesion to PMMA |

Hg or Metal Lamp 400-500↑ |

|

|

|

|

Hard Coating / Etc.

|

|

| Grade |

NV(%) |

Viscosity (cps @25℃) |

Color (APHA) |

Pencil Hardness (at 750g) |

Features |

TDS |

MSDS |

| - |

- |

- |

- |

PET |

PC |

PMMA |

- |

| SSH-0501C |

38 ~ 42 |

<30cps |

250 max |

2H - 3H |

H - 2H |

6H - 7H |

Clear Type |

|

|

| SSH-0502F |

38 ~ 42 |

<30cps |

250 max |

2H - 3H |

H - 2H |

6H - 7H |

Anti-Finger Print Type |

|

|

| SSH-0503G |

38 ~ 42 |

<30cps |

250 max |

2H - 3H |

H - 2H |

6H - 7H |

Anti-Glare Type |

|

|

|

|

UV Adhesives

|

|

| Grade |

Refractive Index |

Viscosity (cps @25℃) |

Features |

Cure Condition (mJ/㎤) |

TDS |

MSDS |

| SSA-3001 |

1.475 - 1.485 |

3,000 |

Plastics (PC-PC) |

Hg or Metal Lamp 400-500↑ |

|

|

| SSA-3007 |

1.467 - 1.477 |

400 |

Plastics (PET-PC, PC-PC, PET-PET) |

Hg or Metal Lamp 400-500↑ |

|

|

| SSA-3009 |

1.470 - 1.480 |

3,000 |

Plastics (PET-PMMA, PET-PET, PMMA-PMMA) |

Hg or Metal Lamp 400-500↑ |

|

|

|

|

Optical Clear Adhesives

|

|

| Grade |

Thickness (㎛) |

Viscosity (cps @25℃) |

Adhesion(gf/25mm) |

Cure Condition |

TDS |

MSDS |

| SSA-2014Z |

125 |

1,200 |

2,800 |

1 step. BL 100mJ/cm2, 2 step. Metal or Mercury 2,000mJ/cm2↑ |

|

|

| SSA-2902 |

50 |

1,300 |

2,000 |

1 step. BL 100mJ/cm2, 2 step. Metal or Mercury 2,000mJ/cm2↑ |

|

|

|

|

Acrylic Polymer

|

|

| Product Name |

Features |

Dilution(%) |

Functionality |

OH Value* |

Color (APHA) |

viscosity

(cps @ 25℃) |

Tg |

Advantage, recommendation points |

TDS |

MSDS |

| SAP-7700HT40 |

Aliphatic Acrylpolymer |

THFA (30%)

HDDA (30%) |

2 |

- |

- |

70,000 ~ 110,000 |

84 |

Good balance with adhesion and hardness |

|

|

| SAP-4400 |

Aliphatic Acrylpolymer |

THFA (35%)

HDDA (35%) |

2 |

- |

- |

1,000 ~ 5,000 |

55* |

Good balance with adhesion and hardness |

|

|

| SAP-M3905 |

Aliphatic Acrylpolymer |

EHA(50%), IBOA (30%) |

1 |

95 - 98 |

- |

3,500 ~ 6,500 |

-39 |

Good adhesion, flexibility. |

|

|

| SAP-M6905 |

Aliphatic Acrylpolymer |

EHA(60%), IBOA (10%) |

1 |

46 - 50 |

- |

3,000 ~ 7,000 |

-69 |

Good adhesion, flexibility. |

|

|

| SAP-3300E30 |

Aliphatic Acrylpolymer |

EAc (70%) |

- |

96 - 99 |

- |

10,000 ~ 15,000 |

-33 |

Good adhesion, flexibility. |

|

|

|

|

Polythiols

|

|

| Product Name |

Features |

SH Value

(g/eq) |

Functionality |

MW (Theoretical Mw) |

Color (APHA) |

viscosity

(cps @ 25℃) |

Refractive index |

Advantage, recommendation points |

TDS |

MSDS |

| ST-031* |

Ester Polythiol |

170~185 |

3 |

525.6 |

<150 |

5,000~8,000 |

1.535~1.536 |

High Tg, good chemical resistance and reactivity |

|

|

| ST-032* |

Ester Polythiol |

128~138 |

3 |

398.6 |

<30 |

100~200 |

1.515~1.516 |

Low viscosity, good adhesion and flexibility |

|

|

| ST-033 |

Ester Polythiol |

330~370 |

3 |

1,430 |

<30 |

150~350 |

1.484~1.486 |

Low stench, low toxicity and good reactivity |

|

|

| ST-034 |

Epoxy Polythiol |

250~300 |

3 |

540 |

<30 |

10,000~20,000 |

1.510~1.520 |

Low stench, low toxicity and good reactivity |

|

|

| ST-035 |

Ester Polythiol |

380~420 |

3 |

1,700 |

<30 |

200~400 |

1.482~1.483 |

Low stench, low toxicity and good reactivity |

|

|

| ST-041* |

Ester Polythiol |

124~130 |

4 |

488.6 |

<30 |

300~500 |

1.528~1.529 |

Good reactivity and fast curing |

|

|

| Product Name |

Features |

SH Value

(g/eq) |

Functionality |

MW (Theoretical Mw) |

Color (APHA) |

viscosity

(cps @ 25℃) |

Refractive index |

Advantage, recommendation points |

TDS |

MSDS |

| ST-036 |

Epoxy Polythiol |

440~490 |

3 |

440.6 |

<30 |

200~400 |

1.500~1.504 |

Good stability and good adhesion. |

|

|

| ST-042 |

Ester Polythiol |

120~140 |

4 |

544.8 |

<30 |

900~1,200 |

1.505~1.515 |

Good stability and reactivity. |

|

|

|

|

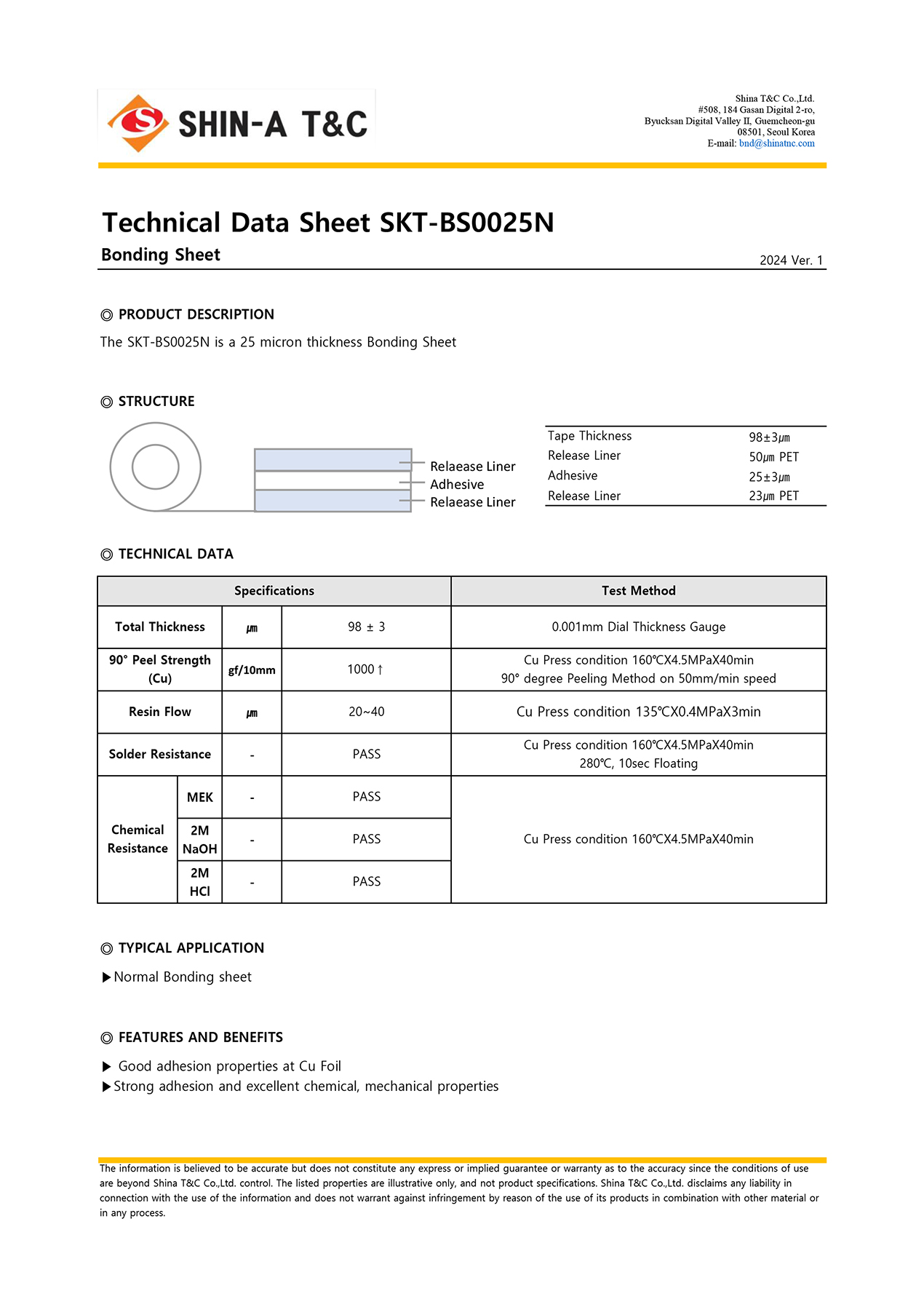

Bonding Sheet

|

|

|

|